Efficient Digging Starts with a Small Garden Excavator

I’m thrilled to have you here! Before we dive into the content, let’s stay connected. Join me on my social media platforms for more insights, community engagement, and regular updates. Here’s where you can find me:

📌 Facebook: Shandong Huaying International Trade Co., Ltd.

Now, let’s embark on this journey together. I hope you find the content here not only insightful and engaging but also valuable to your interests. Let’s learn, grow, and connect!

Table of Contents

Introduction

Excavators play a critical role in the construction and earthmoving industries. They are versatile machines used for digging, lifting, demolition, trenching, and many other tasks. With various models designed for specific applications, understanding the types of excavators available in the market helps businesses and professionals make informed decisions. Choosing the right machine can significantly impact productivity, cost-efficiency, and project success. This blog will explore four expert-approved types of excavators, their key features, benefits, and use cases.

Why Knowing the Types of Excavators Matters

Selecting the wrong type of excavator can lead to inefficiencies, higher operational costs, and potential delays in project timelines. On the other hand, using the right type can enhance efficiency and accuracy, especially in large-scale or technically demanding tasks. Each type of excavator is engineered to meet unique performance requirements based on the working environment. Therefore, understanding the features and limitations of each type can empower contractors and project managers to work smarter and safer.

1. Crawler Excavators: Versatility on Rugged Terrain

Crawler excavators are one of the most common types of excavators and are widely recognized for their ability to operate efficiently on rough and uneven terrain. They run on tracks instead of wheels, providing better balance and stability. These excavators are particularly effective in mining, road construction, and heavy-duty excavation projects where traction and power are essential.

Unlike wheeled counterparts, crawler excavators distribute weight more evenly, which minimizes ground pressure—making them ideal for soft or sensitive terrain like wetlands, clay-rich soils, or forested areas. Their robust undercarriage system allows them to remain stable while lifting or digging at awkward angles or on inclined surfaces. Crawler excavators are also capable of using a wide range of attachments, including rock breakers, augers, and grapples, which increases their versatility across industries.

Construction firms often choose crawler types for long-term use on major infrastructure projects such as dams, highways, and large-scale commercial builds due to their endurance and lower risk of mechanical failure under tough conditions. Despite being slower and harder to transport, their sheer capability on challenging terrain justifies the logistical complexity in many scenarios.

Key Features:

- Operate well on slopes and muddy surfaces

- Suitable for long-term heavy-duty projects

- High horsepower and digging force

- Capable of using multiple hydraulic attachments

- Ideal for projects requiring high traction and stability

Best Use Cases:

- Large construction sites

- Hillside excavation

- Demolition and lifting operations

- Quarry extraction

- Deep foundation work

2. Wheeled Excavators: Speed and Flexibility

Wheeled excavators are similar to crawler types but are mounted on wheels instead of tracks. This makes them ideal for urban construction projects and roadworks, where mobility and speed are essential. Their design prioritizes travel efficiency and minimal damage to paved surfaces, making them especially suited for projects within cities or along transportation corridors.

One of the main advantages of wheeled excavators is their ability to drive between job sites without requiring a trailer or heavy transport equipment. This autonomy can significantly reduce downtime and transportation costs. Operators also appreciate the greater visibility and driving comfort when moving along roads, as the cabins are typically outfitted for higher-speed travel and maneuvering.

Wheeled types of excavators also excel in environments where frequent repositioning is needed. With the ability to perform 360-degree swings and retract their boom for tight maneuvering, they are often used in utility repair, sidewalk replacement, and light demolition work. Some models even come with adjustable outriggers to enhance stability during operation, especially when working off-center.

Key Features:

- Fast relocation between job sites

- Minimal surface damage

- Better fuel efficiency on roads

- Ideal for high-traffic areas

- Can operate in narrow urban streets

Best Use Cases:

- Urban infrastructure work

- Municipal projects

- Road maintenance

- Utility repairs

- Light commercial demolition

3. Mini Excavators: Compact and Efficient

Mini excavators, also known as compact excavators, are smaller in size and designed for light-duty work. Despite their compact frame, they offer powerful digging capabilities and are perfect for tasks where space is limited. These types of excavators are frequently used in residential projects, landscaping, and small utility work, where large machines would be too bulky or impractical.

Their small footprint and lower weight allow them to navigate through garden gates, sidewalks, and tight corridors without damaging existing structures or landscaping. Mini excavators can typically rotate 360 degrees without needing extra space, thanks to their zero- or reduced-tail-swing configurations.

One of the key benefits of mini excavators is their ease of use. Even operators with limited experience can handle these machines effectively with minimal training. Their operational simplicity makes them ideal for short-term rental, DIY construction, and small contractor businesses. Additionally, modern mini excavators are fuel-efficient and produce fewer emissions, aligning with sustainability goals in both urban and rural settings.

Key Features:

- Easy to operate and transport

- Less noise and fuel consumption

- Ideal for tight working spaces

- Zero- or reduced-tail swing models available

- Compatible with small hydraulic tools

Best Use Cases:

- Backyard renovations

- Small trenching work

- Pipe and cable laying

- Garden and landscape design

- Minor building repairs and foundation work

4. Long Reach Excavators: Precision at a Distance

Long reach excavators are designed with extended arms and booms to perform tasks at greater distances. They are specialized machines used in applications where deeper excavation or extended reach is necessary. These types of excavators are ideal for dredging rivers, deep trenching, and demolition at a distance.

The unique structure of long reach models includes reinforced booms and arms capable of reaching 40–100 feet horizontally. This makes them indispensable in areas where standard excavators would either fall short or compromise safety. By keeping the base of the machine far from unstable edges or hazardous zones, operators can perform precise work while remaining in a safe location.

Although they may not match the brute force of crawler excavators, long reach machines compensate with unmatched control and range. They are commonly deployed in waterway maintenance, canal dredging, and clearing vegetation from hard-to-access slopes. Some advanced models include tilt rotators and camera systems that enhance accuracy for underwater or blind-angle operations.

Key Features:

- Extended arm and boom

- Excellent reach for remote tasks

- Reduced need for machine repositioning

- Suitable for operations from a safe distance

- Optional attachments for specialized work

Best Use Cases:

- Riverbank maintenance

- Canal construction

- High-reach demolition

- Underwater excavation

- Environmental cleanup on steep slopes

Comparing the 4 Types of Excavators

To help you decide which type best suits your project needs, the following table compares essential aspects of the four types of excavators:

| Type of Excavator | Terrain Suitability | Size | Best For | Key Advantage |

|---|---|---|---|---|

| Crawler Excavator | Rough, uneven | Large | Mining, road building | Strong digging power |

| Wheeled Excavator | Paved, urban | Medium to large | Urban projects, road works | High mobility on roads |

| Mini Excavator | Limited, confined spaces | Small | Residential work, landscaping | Compact and fuel-efficient |

| Long Reach Excavator | Remote or deep locations | Large | Dredging, high-reach demolition | Extended reach and precision |

How to Choose Among Different Types of Excavators

Choosing among various types of excavators depends on your specific project requirements, the nature of your worksite, and your overall budget. With several types of excavators available in the market, understanding which model aligns with your operational goals is key to achieving success. Here are a few essential considerations to help guide your decision-making process when selecting from the different types of excavators:

Project Scope

Evaluate whether the task involves heavy-duty operations, such as mining or large-scale demolition, or if it’s better suited for light-duty work like landscaping or residential trenching. Certain types of excavators, such as crawler or long reach models, are better equipped for demanding applications, while mini excavators are ideal for smaller, more precise jobs.

Work Environment

The physical conditions of your job site significantly influence the type of excavator you should choose. For example, rough or uneven terrains call for crawler excavators due to their track-based design and stability, while urban or paved environments benefit more from wheeled excavators. Each of these types of excavators is engineered to perform optimally under specific environmental constraints.

Mobility Needs

Some construction projects require frequent relocation of equipment. In such cases, wheeled excavators offer excellent mobility and speed for moving between job sites. On the other hand, types of excavators like crawler excavators, though slower, provide superior traction and balance on uneven ground. Choose the type that aligns with how mobile your operations need to be.

Operational Costs

Different types of excavators have varying fuel efficiency, maintenance requirements, and transportation needs. Mini excavators, for example, are not only more fuel-efficient but also easier and less costly to transport. In contrast, long reach excavators may require more complex logistics but offer unique capabilities. Reviewing operational costs in advance ensures long-term savings and better resource management.

By carefully analyzing these factors, you can select from the types of excavators available to match your project’s unique demands. The right choice will boost productivity, lower costs, and reduce potential project risks. Always consult with machinery experts or manufacturers to ensure you’re making the most informed decision regarding the various types of excavators.

About Shandong Huaying International Trade Co.,Ltd.

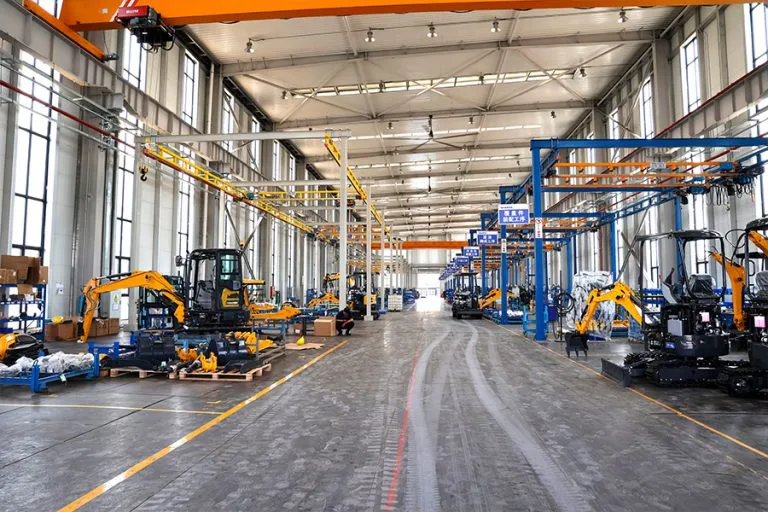

Shandong Huaying International Trade Co.,Ltd. is a leading integrated trading and manufacturing company based in Linyi, Shandong Province, China. Covering an area of 50,000 square meters and employing 150 skilled professionals, the company specializes in producing high-performance equipment including excavators, electric forklifts, and lawn mowers. With exports to the United States, Canada, Germany, France, Italy, the United Kingdom, Chile, and Ecuador, we are committed to providing reliable machines tailored to diverse global markets.

Conclusion

Understanding the different types of excavators is critical to achieving optimal performance on any construction or earthmoving project. Whether you need the raw power of a crawler excavator or the compact efficiency of a mini excavator, selecting the right machine will enhance efficiency and reduce operational challenges. By considering your site conditions, project goals, and budget, you can confidently choose from these expert-approved types and ensure project success.

FAQ

What are the common types of excavators available in the market?

The main types of excavators include crawler excavators, wheeled excavators, mini excavators, and long reach excavators. Each type is suited for different working environments and project needs.

How do I choose the right type of excavator for my project?

Consider factors such as terrain conditions, scope of work, mobility requirements, and budget. For example, crawler excavators are ideal for rugged terrain and heavy-duty tasks, while mini excavators suit small-scale projects with limited space.

What is the difference between wheeled and crawler excavators?

Wheeled excavators offer better mobility and speed on paved surfaces and urban sites, whereas crawler excavators provide superior traction and stability on uneven or soft ground.

What kinds of tasks are mini excavators best suited for?

Mini excavators are compact and easy to maneuver, making them perfect for landscaping, small trenching, pipe laying, and residential construction work.

What are long reach excavators mainly used for?

Long reach excavators have extended arms for tasks that require working at a distance, such as river dredging, deep trenching, high-reach demolition, and environmental cleanup.