Table of Contents

Introduction

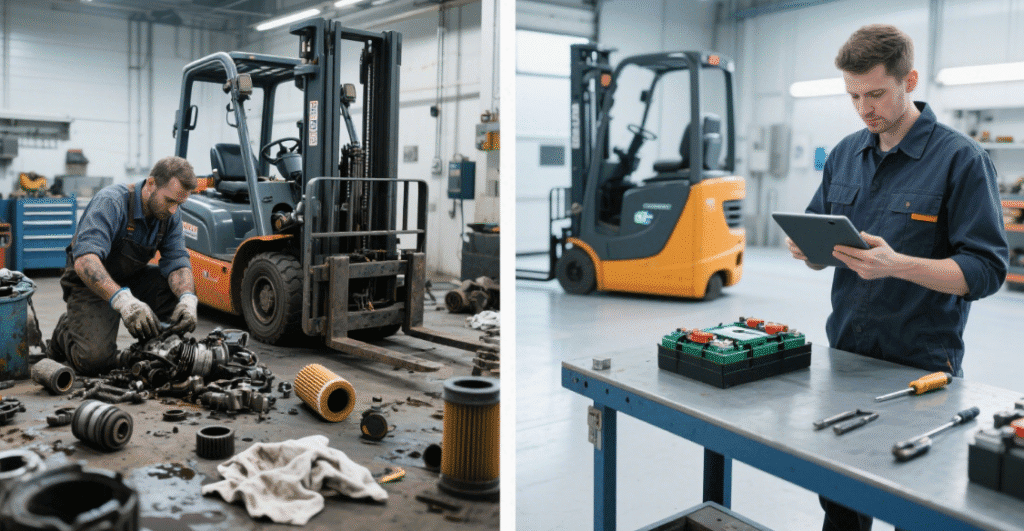

In recent years, businesses have become increasingly aware of the need to adopt environmentally friendly practices, especially when it comes to material handling and warehouse operations. One of the most significant innovations in the field is the rise of electric motor rider forklifts, which have proven to be a more sustainable option compared to traditional internal combustion forklifts. These advancements not only align with corporate sustainability goals but also offer a range of operational benefits.

This blog explores the environmental advantages of electric motor rider forklifts over internal combustion models, and why more companies are making the switch to greener alternatives. We’ll also delve into how Shandong Huaying International Trade Co., Ltd.’s high-quality electric forklifts are making a difference in the global market.

The Environmental Impact of Internal Combustion Forklifts

Internal combustion (IC) forklifts, while widely used across industries, present several environmental challenges that cannot be overlooked. These include significant carbon emissions, noise pollution, and high fuel consumption. While they have been the go-to choice for material handling in many sectors, their environmental footprint has become increasingly difficult to ignore. With rising concerns about global warming and stricter environmental regulations, businesses are looking for more sustainable alternatives.

1. Carbon Emissions

One of the most significant environmental drawbacks of internal combustion forklifts is their reliance on fossil fuels. These forklifts burn gasoline, diesel, or propane, which directly contributes to the release of greenhouse gases (GHGs) such as carbon dioxide (CO2) into the atmosphere. The carbon emissions from these machines not only contribute to global warming but also worsen air quality. This is especially concerning for businesses operating in urban areas or regions with stringent environmental policies. As countries around the world aim to meet carbon reduction targets, industries relying on IC forklifts are under increasing pressure to adopt cleaner alternatives.

For businesses aiming to reduce their carbon footprint, relying on IC forklifts becomes a significant challenge. The amount of carbon dioxide emitted over the lifespan of these machines can far exceed that of their electric counterparts, adding up to substantial environmental costs. Moreover, in areas with carbon taxes or emission regulations, companies using internal combustion forklifts may face additional financial burdens due to fines or regulatory penalties.

2. Air and Noise Pollution

In addition to carbon emissions, internal combustion forklifts release other harmful pollutants into the air, such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. These pollutants can be hazardous to human health, contributing to respiratory diseases and cardiovascular problems among workers. Furthermore, the emission of particulate matter worsens the overall air quality in and around industrial facilities, contributing to smog and haze, particularly in urban areas.

Noise pollution is another significant concern with internal combustion forklifts. These forklifts generate high levels of noise during operation, which can create a stressful and uncomfortable working environment. In indoor warehouses and factories, this noise can lead to worker fatigue, decreased productivity, and long-term hearing damage. In environments where noise regulations are in place, such as residential areas or industrial parks, the use of IC forklifts may require additional noise mitigation efforts, further driving up operational costs.

3. Fuel Dependency

Internal combustion forklifts depend on non-renewable fuel sources such as gasoline, diesel, or propane. This reliance on fossil fuels not only contributes to environmental degradation but also poses economic challenges. Fuel costs can fluctuate significantly based on global oil prices, making it difficult for businesses to predict and control their operational expenses. Moreover, as the global push for energy independence and sustainability grows, continued reliance on fossil fuels goes against the grain of future-facing businesses looking to reduce their environmental impact.

In the long run, businesses that rely on internal combustion forklifts face mounting operational costs due to fuel dependency. These forklifts also require regular fueling, creating logistical challenges, particularly in larger warehouses or facilities that operate around the clock. Moreover, storing and handling fuel adds additional complexity to operations, requiring specialized equipment and safety protocols to prevent accidents and ensure compliance with safety regulations.

The Rise of Electric Motor Rider Forklifts

Electric motor rider forklifts, like the ones offered by Shandong Huaying International Trade Co., Ltd., have emerged as a powerful solution for businesses seeking to minimize their environmental impact. These forklifts run on electricity, making them a cleaner, quieter, and more cost-efficient alternative to their internal combustion counterparts.

1. Zero Exhaust Emissions

One of the standout features of electric motor rider forklifts is their zero exhaust emissions. Unlike their internal combustion counterparts, these machines do not burn fossil fuels, meaning they do not emit harmful gases such as carbon monoxide, carbon dioxide, or nitrogen oxides. This makes electric forklifts an excellent choice for businesses aiming to improve air quality in their warehouses, factories, and distribution centers.

Electric forklifts are especially advantageous in indoor environments where air quality is critical. As they produce no harmful exhaust, these machines ensure that workers are not exposed to dangerous fumes. This leads to a healthier, safer work environment, reducing the risks of respiratory illnesses and improving overall employee well-being.

2. Reduced Noise Pollution

Electric forklifts operate at significantly lower noise levels compared to internal combustion forklifts. While IC forklifts generate a loud engine noise that can reach up to 85 decibels or more, electric motor rider forklifts are much quieter, typically operating at around 60-65 decibels. This reduction in noise pollution makes electric forklifts a preferred choice for businesses operating in noise-sensitive environments, such as indoor warehouses, retail spaces, or manufacturing plants with limited space.

The quieter operation of electric forklifts also contributes to improved worker comfort and safety. With less noise pollution, employees are less likely to suffer from stress or hearing damage, which can lead to increased productivity and a more pleasant working atmosphere.

3. Energy Efficiency

Electric motor rider forklifts are far more energy-efficient than internal combustion models. These forklifts convert a higher percentage of the energy from the power source into usable mechanical work. This means that electric forklifts consume less energy to perform the same tasks as their IC counterparts, reducing both operational costs and energy waste.

The high energy efficiency of electric forklifts makes them a more sustainable option for businesses seeking to reduce their carbon footprint. With lower energy consumption, electric forklifts can contribute to substantial cost savings over the long term, making them a more attractive investment for companies focused on cost control and environmental responsibility.

Key Advantages of Electric Motor Rider Forklifts

Let’s explore in greater detail why electric motor rider forklifts are becoming the preferred choice for eco-conscious businesses worldwide.

1. Environmental Benefits

Electric motor rider forklifts are powered by electricity, a clean and renewable energy source. This reduces businesses’ reliance on fossil fuels and helps them meet sustainability targets while reducing their carbon footprint. As more countries implement stricter emissions regulations, electric forklifts provide a straightforward solution to ensure compliance and avoid penalties.

2. Lower Maintenance Costs

Since electric forklifts do not have the complex engine parts found in internal combustion forklifts, they require less maintenance. This not only lowers operational costs but also extends the lifespan of the equipment. For example, Shandong Huaying International Trade Co., Ltd.’s range of electric forklifts, such as the 2 Ton Electric Forklift LH-F20 and 3 Ton Electric Forklift LH-F30, are designed with durability and low-maintenance in mind.

3. Improved Indoor Air Quality

Electric forklifts produce no harmful emissions, making them ideal for indoor use. By eliminating exhaust gases, electric forklifts contribute to healthier air quality, reducing the risk of respiratory issues among workers. This is especially crucial in enclosed spaces, where ventilation can be limited.

4. Compliance with Green Regulations

As governments around the world enforce stricter environmental regulations, businesses must adopt cleaner technologies to remain compliant. Electric forklifts offer a simple solution to meet these growing standards, ensuring that companies can avoid fines and stay ahead of regulatory changes. By switching to electric forklifts, businesses not only improve their environmental impact but also demonstrate a commitment to sustainable practices.

Comparing Electric Motor Rider Forklifts vs. Internal Combustion Forklifts

Here’s a detailed comparison of electric motor rider forklifts versus internal combustion models:

| Feature | Electric Motor Rider Forklifts | Internal Combustion Forklifts |

|---|---|---|

| Emissions | Zero emissions | High carbon emissions |

| Noise Level | Low noise | High noise |

| Maintenance Costs | Lower maintenance | Higher maintenance |

| Energy Source | Electricity (renewable) | Fossil fuels (non-renewable) |

| Operational Efficiency | Higher energy efficiency | Lower energy efficiency |

| Indoor Use | Ideal for indoor environments | Not suitable for indoor use |

| Environmental Compliance | Meets stricter environmental regulations | May struggle with compliance |

Shandong Huaying International Trade Co., Ltd.’s Electric Forklifts

As a leader in manufacturing electric motor rider forklifts, Shandong Huaying International Trade Co., Ltd. offers a diverse range of models designed to meet the unique needs of different industries. Our electric forklifts, including the 2 Ton Electric Forklift LH-F20, 2.5 Ton Electric Forklift LH-F25, and 3.5 Ton Electric Forklift LH-F35, are all eco-friendly, energy-efficient, and low-maintenance, making them the perfect solution for modern businesses committed to sustainability.

Why Choose Shandong Huaying International Trade Co., Ltd.?

- Innovative Design – Our electric forklifts are built with the latest technology to ensure optimal performance, durability, and energy efficiency.

- Customizable Solutions – We offer customized products and services to meet your business’s unique needs, ensuring maximum productivity and cost savings.

- Global Reach – With over 500,000 machines sold worldwide, our products are trusted by businesses in countries across North America, Europe, and Latin America.

- Technical Support – Our dedicated technical team is always available to assist with product customization, installation, and troubleshooting.

Conclusion

Electric motor rider forklifts are a more environmentally friendly and cost-effective solution for modern material handling needs compared to internal combustion forklifts. With zero emissions, lower maintenance costs, and improved energy efficiency, these forklifts are helping businesses around the world achieve their sustainability goals while also boosting operational efficiency.

If you’re ready to make the switch to an eco-friendly forklift solution, Shandong Huaying International Trade Co., Ltd. can provide the right equipment for your business. Our range of electric forklifts offers high-quality, reliable, and customizable solutions to meet your unique material handling needs.

FAQ

1. Are electric forklifts as powerful as internal combustion forklifts?

Yes, electric motor rider forklifts are highly efficient and provide sufficient lifting power for most warehouse operations.

2. How long does the battery of an electric forklift last?

The battery life depends on the forklift model and usage but generally lasts between 5-7 years with proper maintenance.

3. Can electric forklifts be used outdoors?

Yes, many electric forklifts are designed for both indoor and outdoor use, although some may have limitations in extreme weather conditions.

4. What are the charging times for electric forklifts?

Charging times vary depending on the forklift’s battery capacity but typically range from 6-8 hours for a full charge.

5. How do electric forklifts contribute to sustainability?

Electric forklifts reduce carbon emissions, improve energy efficiency, and help businesses meet environmental regulations, making them an essential part of any green initiative.

If you’re interested in learning more about our electric forklifts or would like to request a quote, don’t hesitate to contact us today!

Thank you for reading! If you found this content valuable, let’s keep the conversation going. For more insights, industry trends, and updates from Shandong Huaying International Trade Co., Ltd., be sure to connect with us on social media:

📌 Facebook: Shandong Huaying International Trade Co., Ltd.

We look forward to sharing more knowledge and opportunities with you. Let’s continue learning, growing, and innovating—together.